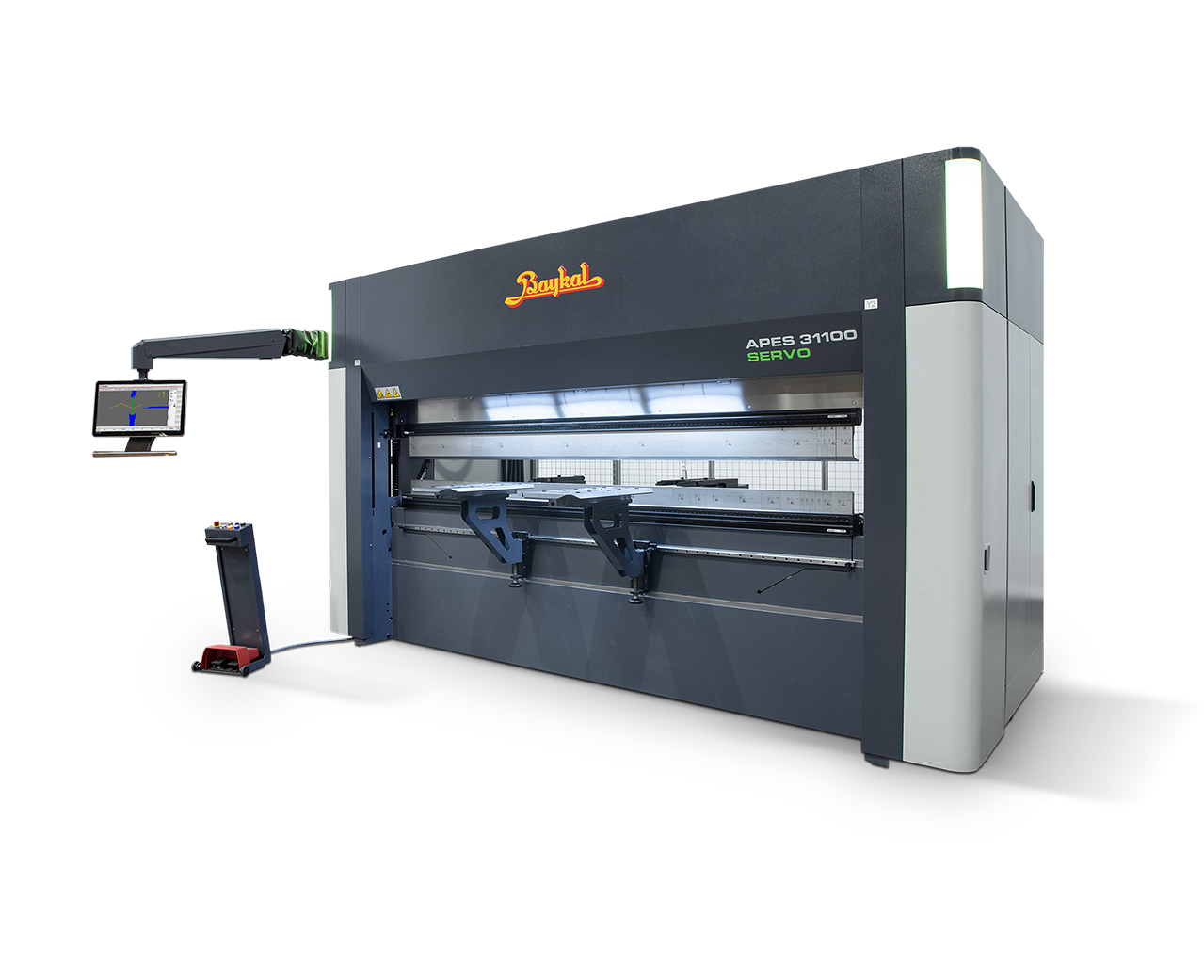

Energy Saving:

- Less energy consumption and less material waste = Less CO2

- 50 % less energy consumption in average compare to the traditional Hydraulic press brakes

- High energy-saving

Efficiency:

- High efficiency = Less machine usage for the same production volume

- 30 % less processing time in average and short installation time

- Easy programming and high precision = less material waste

Part Quality:

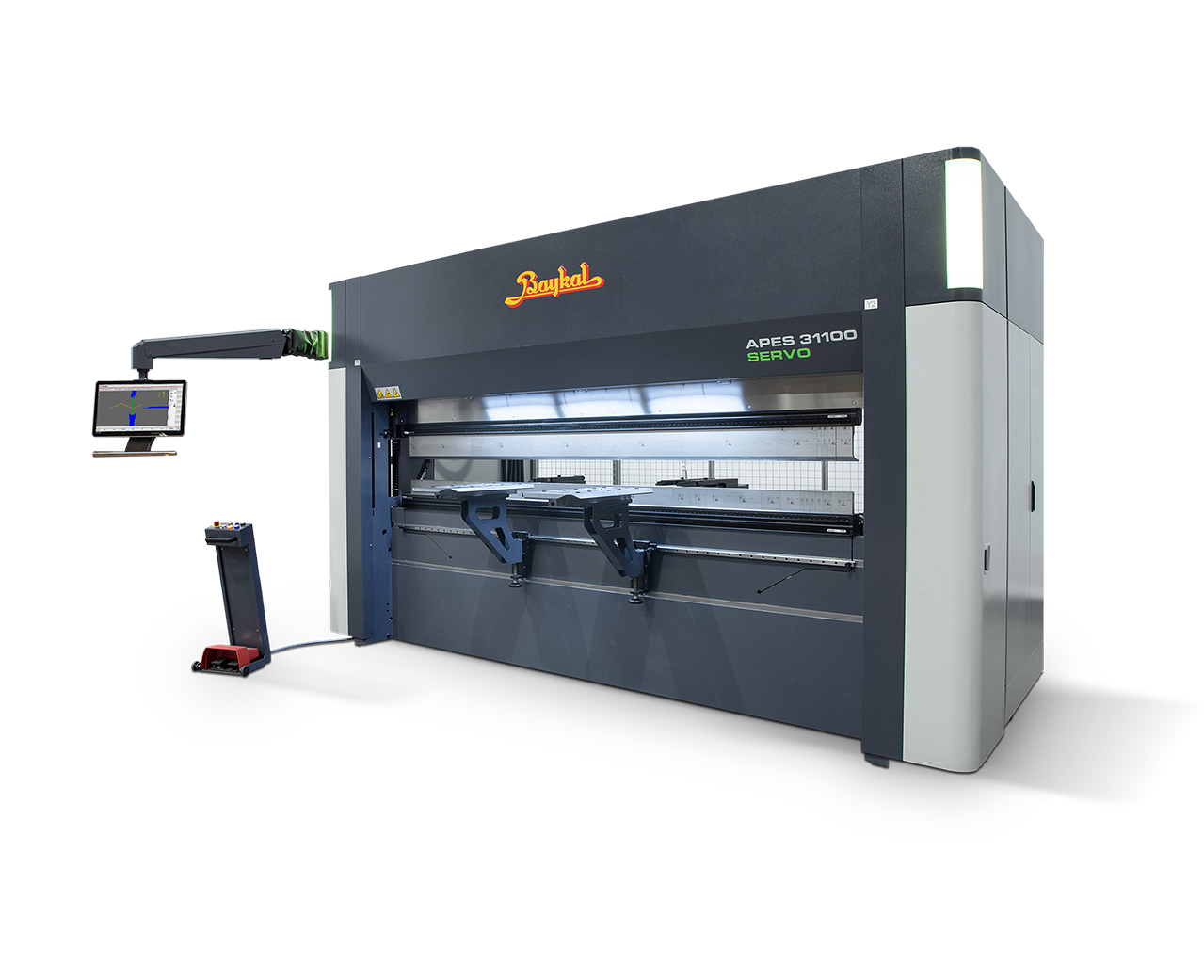

- O-Type frame design and highly repeatable precision thanks to servo-electrical drivers and different tool systems

Low Maintenance Cost:

- No hydraulic oil = no damaging waste

- Compare to the Hydraulic machines, there are less precious and critical parts

- Easiness of cooling

- Operational Safety

Flexibility:

- There is no limitation of throat gap for the long parts

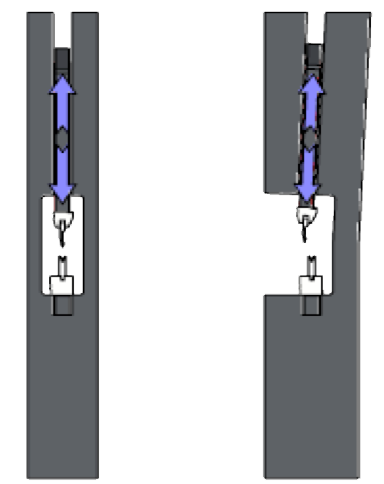

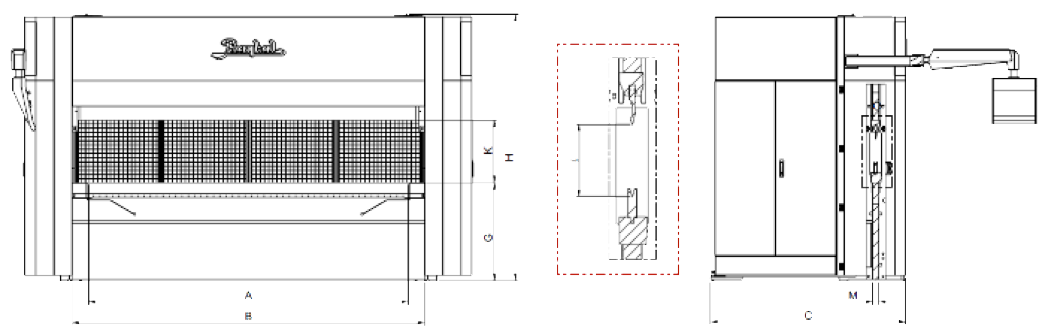

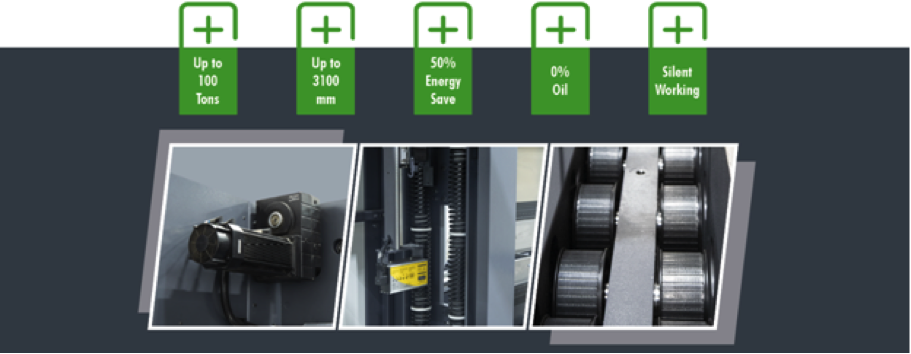

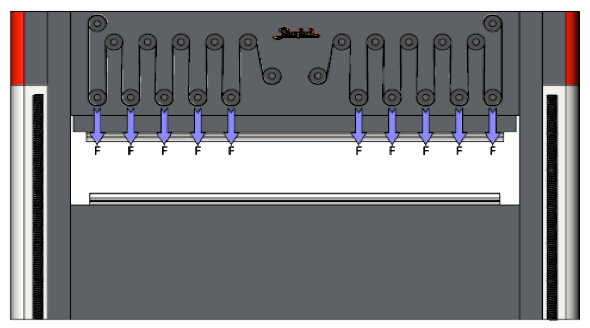

The belt and pulley drive system works with two synchronized servo motors which transfer the force to the upper beam from belt and pulley movements. During the movement of the upper beam, servo motors coil the belt to the main pulley and apply the bending force with even distribution of tonnage across the entire bed length, which allows eliminating almost any need for crowning in the system. That’s why crowning systems are optional for APES SERVO due to the material being used. The return force, which is mechanical for the upper beam, comes from the springs which are located on both sides of the machine, which provides up to %50 energy savings and low CO2 emissions.

APES SERVO Press Brake is designed as closed “O” frame. Instead of C frame, O frame is much more rigid, which reduce and eliminate any deflection in the ram and bed of the machine even under full loaded tonnage, which leads high consistency and high positioning accuracy.

Another benefit of O frame construction design is to allow entire bed length to work with.